scpmkj@gmail.com

Get A Free Quote

Intelligent production, efficient on the code! K11 paging inkjet printer innovates multi industry identification solution

The accuracy, efficiency, and adaptability of product labeling on production lines in industries such as food, medicine, and daily chemical directly affect capacity upgrading and compliance management. Recently, the K11 paging inkjet printer launched by Shicai has become a new choice for small and medium-sized enterprises to reduce costs and increase efficiency, injecting new momentum into the upgrading of industry identification technology with its integrated design of "paging+inkjet", multi scene adaptability, and intelligent operation experience.

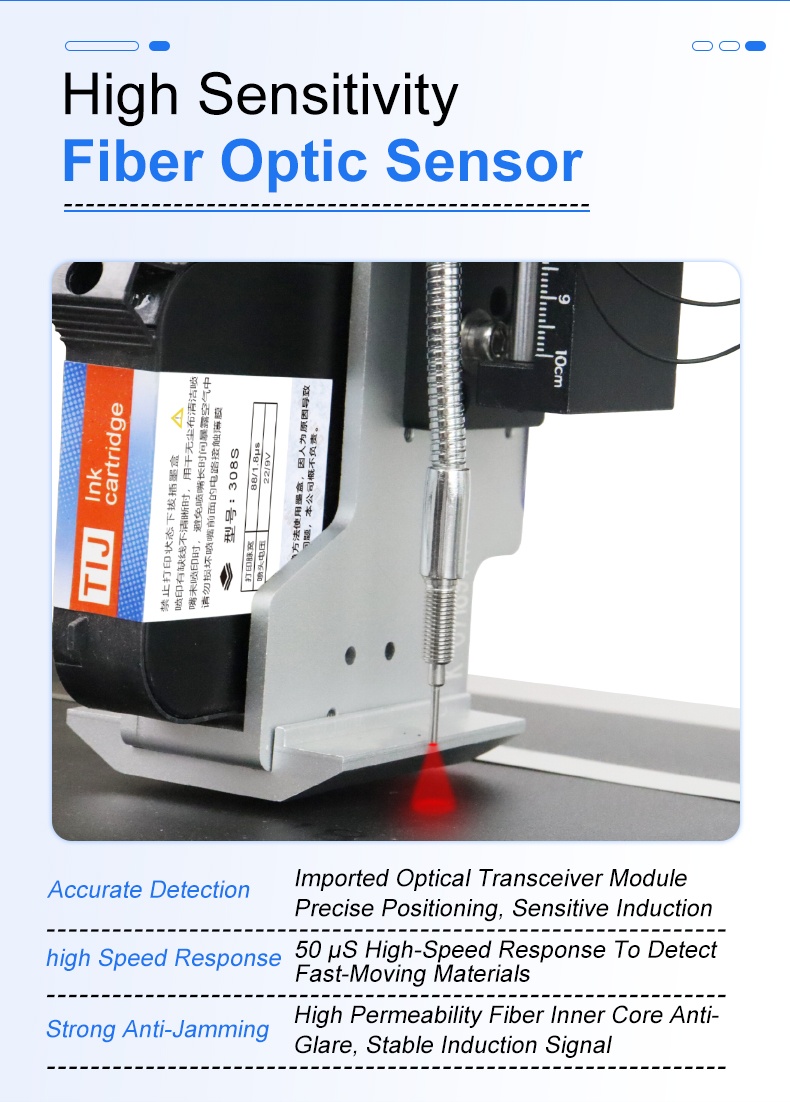

The core advantage of the K11 paging inkjet printer lies in its integrated and efficient operation, which deeply integrates paging and inkjet functions, completely solving the pain points of traditional equipment paging lag and inkjet lag. The precise pagination technology it is equipped with can achieve orderly separation without missing or duplicate pages, whether it is thin as paper manuals, flexible food packaging bags, or hard metal cans and cardboard boxes. With a high-speed printing capacity of 100 meters per minute, it can easily adapt to the operational needs of 24-hour continuous production lines. In terms of printing effect, the equipment adopts high-resolution nozzles, and the character height can be flexibly adjusted between 2-12.7mm. It supports 1-5 lines of information printing, whether it is production date, batch number, supervision code, brand logo, or QR code, it can achieve clear, sharp, wear-resistant and waterproof printing effect. Even after warehouse stacking and logistics bumps, it is not easy to blur, completely eliminating customer complaints caused by identification problems.

The convenience of operation and adaptability to different scenarios are another major highlight of the K11 color recognition system. The device is equipped with a sensitive touch screen that supports multiple input methods such as full spelling and location codes. Text, numbers, Chinese and English, graphics, and other content can be edited directly on the interface, and even novice technicians can quickly get started with the operation. It is compatible with various materials such as plastic, metal, paper, wood, etc., covering multiple industries such as food, medicine, toys, daily chemical, hardware and machinery. It can meet the production date coding of the food industry, the regulatory code printing of pharmaceutical companies, and also adapt to the brand identification of gift packaging and the specification labeling of pipes, truly realizing the multi-functional application of "one machine for N machines". At the same time, the device supports the storage function of 100 text messages and 36 graphics, which can quickly switch the printing parameters of different products, greatly improving the efficiency of changing production lines for multiple batches.

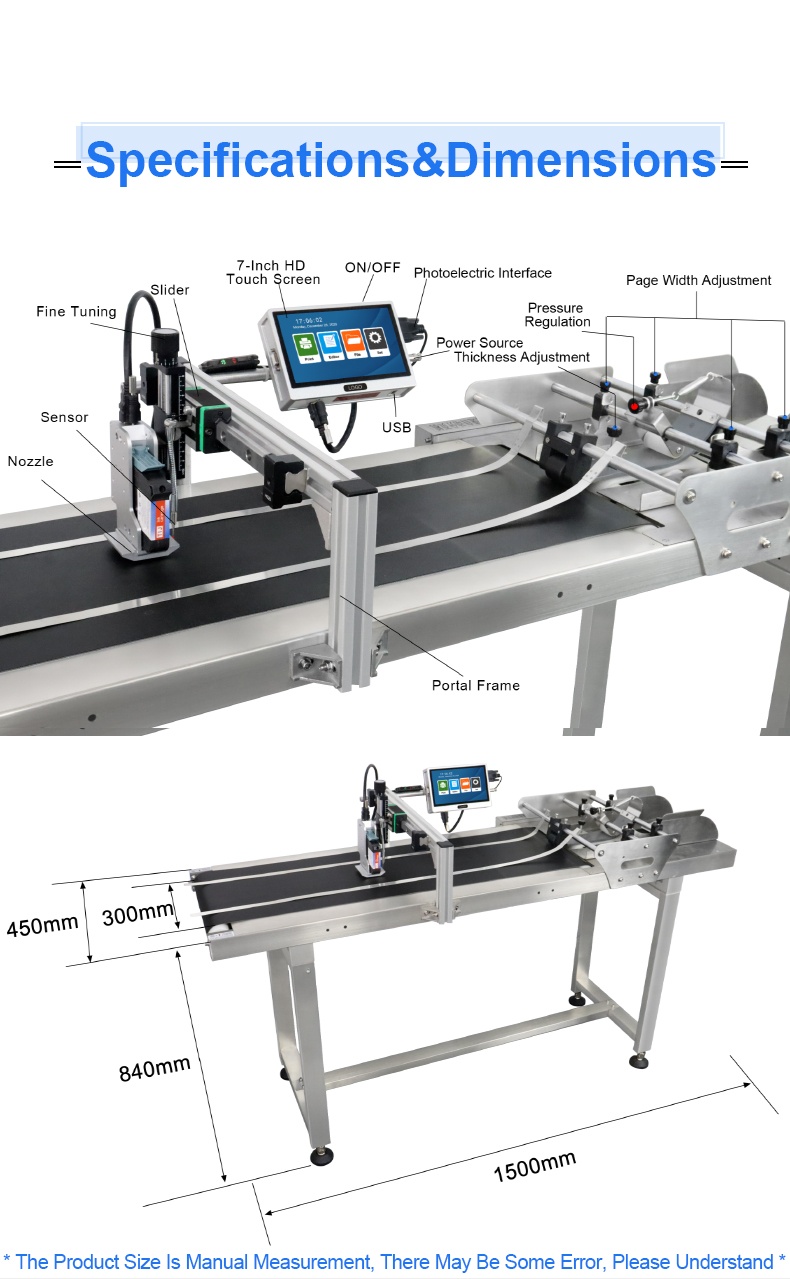

As a brand dedicated to the research and development of spray coding technology, Shicai fully considers the actual needs of small and medium-sized enterprises in the design of K11 page printing machine: the compact body design (20211961.2mm) does not take up too much space, the stainless steel chassis has IP54 protection level, can adapt to complex production environments with 0-40 ℃ and low condensation, and is equipped with one-year warranty after-sales service to provide guarantee for stable production of enterprises. From the high-speed date printing of Zongzi packaging bags, to the regulatory code assignment of drug packaging boxes, and to the batch identification of hardware products, color recognition K11 is becoming a good helper for more and more enterprises with its core advantages of "efficiency, accuracy, and ease of mind".

Under the trend of intelligent manufacturing, identification technology, as an important link in product traceability and brand management, directly affects the market competitiveness of enterprises in terms of efficiency and quality. The K11 page printing machine for color recognition has broken the functional limitations of traditional printing equipment through technological innovation. It not only reduces the equipment procurement and operation costs of enterprises, but also improves production efficiency and product compliance, providing a cost-effective identification solution for the digital transformation of small and medium-sized enterprises. In the future, with the continuous iteration of coding technology, it is believed that intelligent devices that combine practicality and economy will release value in more segmented fields and promote the overall improvement of industry production efficiency.