scpmkj@gmail.com

Get A Free Quote

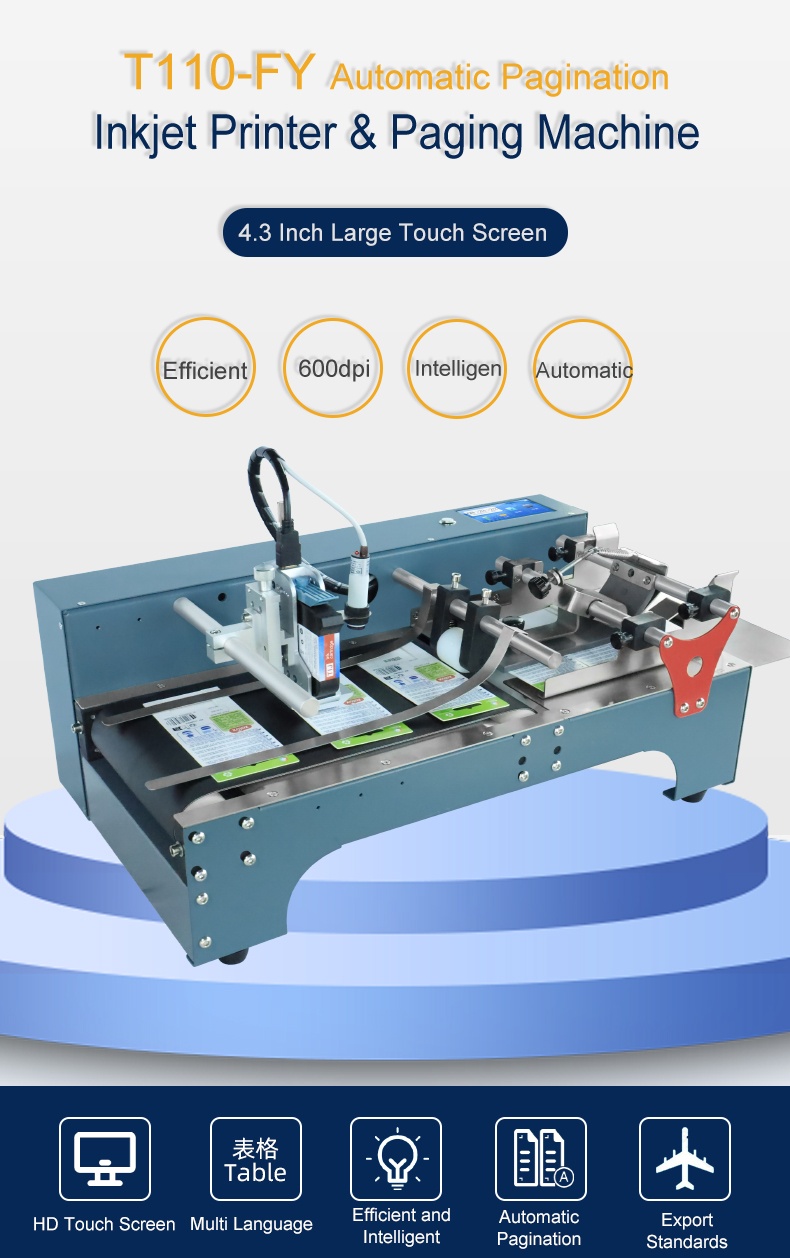

Intelligent integration+full scene adaptation automatic pagination inkjet printer leads the revolution of identification automation

With the upgrading of product traceability compliance requirements in industries such as food, medicine, and daily chemical, as well as the surge in demand for flexible production, automatic pagination coding machines have become the core equipment for intelligent transformation of production lines with their full process closed-loop capabilities of "pagination coding detection removal". Since 2025, the new generation of equipment that integrates high-speed pagination technology, precise coding systems, and intelligent detection modules has accelerated its popularization, promoting the industry's production efficiency to increase by more than three times and reducing the defect rate to below 0.5%, becoming a key lever for enterprises to reduce costs, increase efficiency, and upgrade compliance.

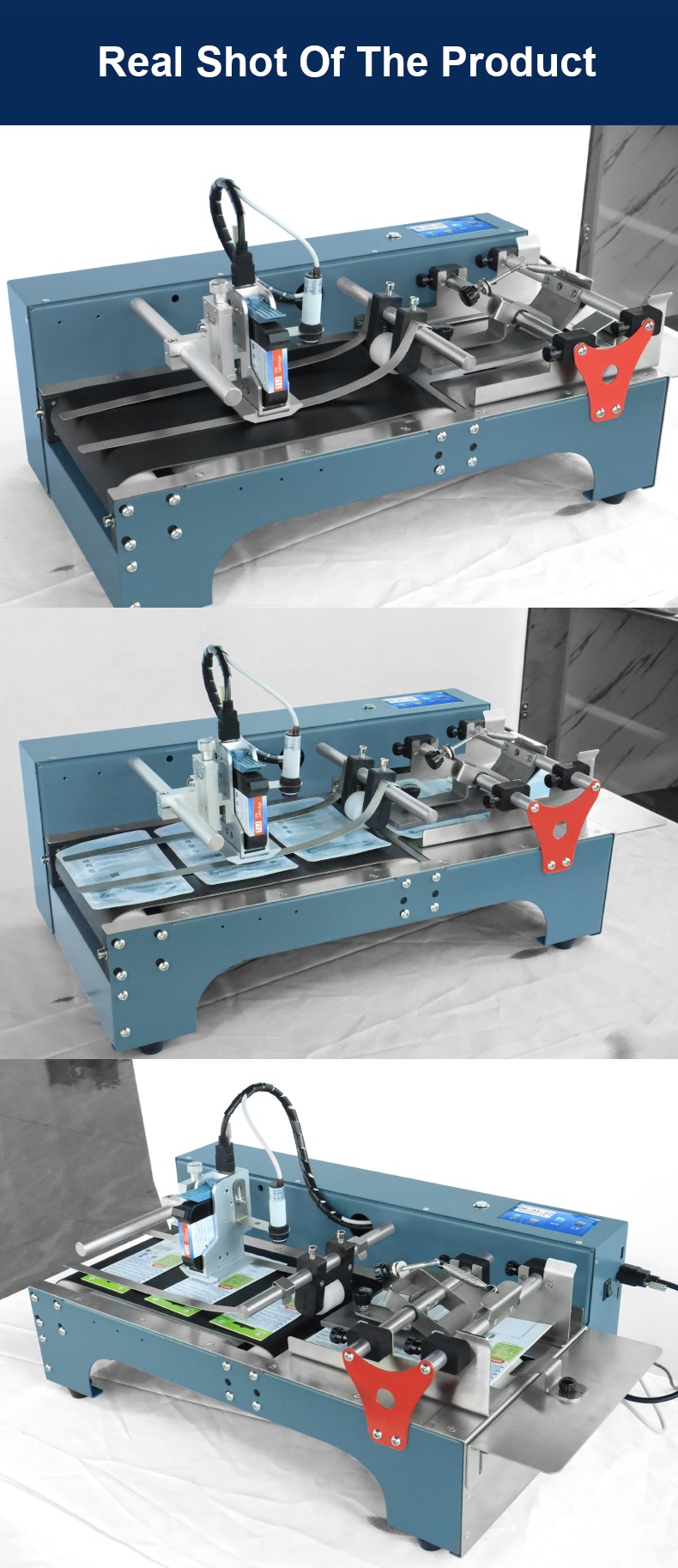

Technological innovation solves pain points in multiple industries. Traditional manual pagination coding is not only inefficient, but also prone to blurring and positional deviation due to stacking deviation and poor material compatibility. Nowadays, mainstream automatic pagination inkjet printers have achieved multiple technological breakthroughs: the pagination module innovatively adopts multiple structural designs such as friction type and reverse wheel type, which can flexibly adapt to soft and hard materials such as paper boxes, food bags, woven bags, and even solve industry problems such as thin paper wrinkles and plastic film electrostatic adsorption. The coding unit is equipped with a 1200DPI high-resolution nozzle and dynamic calibration technology. Under high-speed transportation of 150 meters per minute, the printing deviation is controlled within ± 1mm. The minimum module for QR codes is only 0.2mm, and the scanning pass rate is stable at over 99.8%. There is also equipment integrated with 3D surface compensation technology, which successfully overcomes the problem of coding on the uneven surface of woven bags through adaptive adjustment of nozzle height. After a 50N tensile test, it still did not fall off.

Full process automation has become the core competitiveness. The new generation of equipment generally adopts an integrated design of "pagination coding detection exclusion material collection", equipped with PLC control system and touch screen operation interface, reducing the production adjustment time to within 8 minutes, and the operator can complete parameter settings in 5 minutes. The visual inspection system, relying on self-learning algorithms, can accurately identify problems such as missing codes, blurriness, and printing defects. It automatically separates non-conforming products through blowing or flipping modules. After application, the labeling qualification rate of a certain food packaging enterprise jumped from 89% to 99.6%. At the same time, the equipment supports seamless integration with MES and ERP systems, and can automatically retrieve order data for printing traceability codes, UDI codes, and other information, achieving real-time synchronization of production data and meeting the flexible production needs of multiple batches and small batches.

The expansion of the industry is driven by both policy and market factors. Regulations such as the Food Safety Law and the Drug Traceability Management Measures require product labeling to be traceable, coupled with strict environmental policies on ink safety, promoting an average annual increase of 27% in the configuration rate of automatic pagination inkjet printers in the food and pharmaceutical industries. In terms of terminal demand, over 60% of large-scale enterprises are willing to pay a premium for automated identification equipment, which can reduce labor input by 80%, and the 90 day no cleaning design reduces maintenance costs. The investment return cycle for small and medium-sized manufacturers is generally shortened to 10-12 months. The application scenarios continue to expand, from printing the production date of food bags and assigning electronic supervision codes to medicine boxes, to tracing woven bags for building materials and identifying the qualification certificate of household dust bags, forming a market space of billions.

Industry analysis indicates that in the future, automatic pagination inkjet printers will be upgraded towards "higher speed, higher precision, and more intelligent interconnection". The deep integration of IoT technology will enable remote monitoring and fault warning of devices, and modular design will support more customized needs. As a key identification equipment that links production, circulation, and consumption, the automatic pagination inkjet printer is not only reshaping the industry's production mode, but also laying a solid technical foundation for the product quality traceability system, promoting the intelligent and compliant high-quality development of the manufacturing industry.