scpmkj@gmail.com

Get A Free Quote

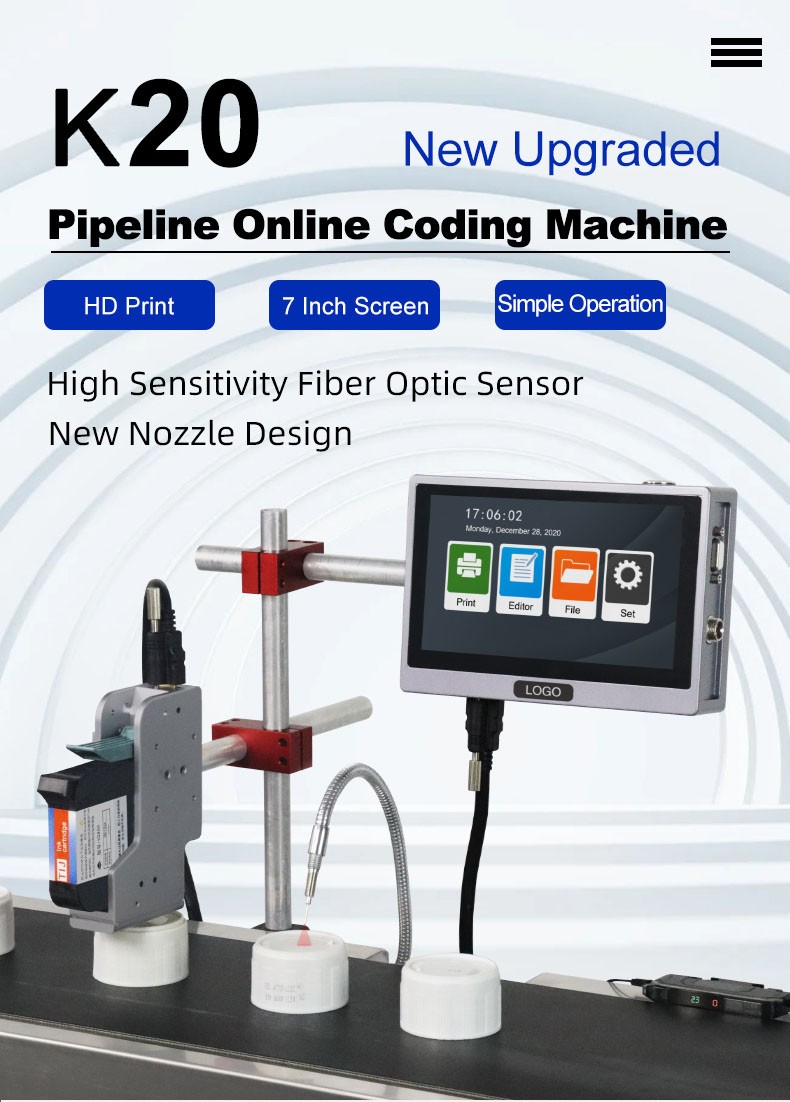

Laser empowerment, green production! K20 laser coding machine leads a new revolution in industrial labeling, environmental protection, and intelligent technology

Driven by both intelligent manufacturing and environmental policies, the field of industrial labeling is entering a critical stage of technological iteration. Laser coding technology, with its advantages of no consumables, high stability, and long-lasting labeling, has maintained an annual market share growth rate of 10-15%, becoming the core force to replace traditional inkjet equipment. Recently, the K20 laser coding machine, which has attracted industry attention, was officially unveiled. With three core highlights of "high efficiency and precision, environmental protection and low consumption, and flexible adaptation", it provides one-stop labeling solutions for multiple industries such as food and beverage, medicine, electronics, and building materials, reshaping the efficiency and environmental standards of industrial labeling.

As a representative of practical laser marking equipment, the K20 laser coding machine is equipped with a sealed CO ₂ laser, with output power ranging from 10W-30W and multiple gear options. Combined with a high-speed scanning galvanometer system, it achieves a dynamic printing speed of up to 100 meters per minute. Its minimum line width of 0.04mm and minimum character printing capacity of 0.3mm enable clear engraving of production dates, batch numbers, supervision codes, QR codes, and other information. Even on small electronic components or flexible packaging surfaces, it can maintain wear-resistant, scratch resistant, and long-lasting color retention, completely solving the pain points of traditional inkjet printing that are prone to blurring and wiping. For multi batch production needs, the equipment supports multiple printing modes such as variable text, database linkage, and garbled anti-counterfeiting. The 140 * 140mm large printing area can meet the simultaneous printing of 1-5 lines of information, greatly improving production line switching efficiency.

Environmental protection and low-cost operation are the core competitiveness of K20. Adopting pure laser marking technology, without the need for consumables such as ink and solvents, VOC emissions are eliminated from the source, perfectly meeting the requirements of environmental policies such as the "14th Five Year Plan" VOCs comprehensive management plan. At the same time, the equipment has no expensive and vulnerable parts, and only requires routine cleaning and maintenance. The long-term use cost is reduced by more than 40% compared to traditional inkjet equipment, reducing the operation and maintenance pressure for small and medium-sized enterprises. In terms of structural design, K20 adopts high-quality stainless steel and aluminum alloy body, which combines IP protection performance and compact size, and can adapt to complex production environments with 0-45 ℃ and low condensation. With adjustable marking heads, it can be quickly installed and adapted for both simple production lines and complex integrated equipment, without occupying too much space.

The ease of operation and adaptability to multiple scenarios make K20 more market penetrating. The device is equipped with a 10.4-inch high-definition touch screen, supporting multi interface data input such as USB, RS232 serial port, SD card, etc. It can directly edit Chinese and English, graphics, barcodes and other content offline without the need for additional PC configuration, making it easy for beginners to get started quickly. It is compatible with paper, aluminum foil PET、 Various non-metallic materials such as glass, wood, and building materials are widely used in applications such as date coding for food packaging, regulatory traceability in the pharmaceutical industry, anti-counterfeiting labeling for electronic products, and specification labeling for building materials and pipes, truly achieving the goal of "one device adapting to the entire industry chain". In addition, the design of multiple external triggering and control output interfaces supports the online operation of multiple devices, meeting the efficient collaboration requirements of large-scale production lines.

At present, the market size of Chinese inkjet printers is steadily expanding, and it is expected to exceed 6.8 billion yuan by 2025, of which the application scale of laser inkjet printers in emerging fields is expected to exceed 1.2 billion yuan. The launch of K20 laser coding machine not only conforms to the development trend of industry intelligence and environmental protection, but also precisely matches the core demand of small and medium-sized enterprises to "reduce costs and increase efficiency". From high-speed production lines for food and beverage to compliance tracing in the pharmaceutical industry, from precise labeling of electronic components to wear-resistant markings on building materials, K20 is becoming a production standard for more and more enterprises due to its high cost-effectiveness and stability.

In the future, with the deep integration of industrial Internet and identification technology, the inkjet equipment will continue to upgrade in the direction of data interconnection and intelligent diagnosis. The K20 laser coding machine, with its modular design and flexible expansion capabilities, can seamlessly integrate with MES/ERP systems, laying the foundation for enterprises to build a full process traceability system. Under the dual opportunities of accelerating domestic substitution and upgrading environmental protection requirements, this type of practical and innovative laser marking equipment will undoubtedly promote the industrial marking industry to enter a new stage of development that is more efficient, environmentally friendly, and intelligent.