scpmkj@gmail.com

Get A Free Quote

P70 piezoelectric inkjet printer: high-definition and efficient, empowering intelligent identification in multiple industries

In modern production scenarios such as food packaging traceability, electronic component labeling, and logistics carton coding, the P70 piezoelectric inkjet printer has become the core equipment for enterprises to achieve automated labeling with its precise printing technology and flexible adaptability. It takes piezoelectric crystal driving technology as its core, completely changing the operating logic of traditional identification equipment, balancing high-definition quality and efficient production capacity, and adapting to diverse needs from small and medium-sized batch customization to large-scale assembly lines.

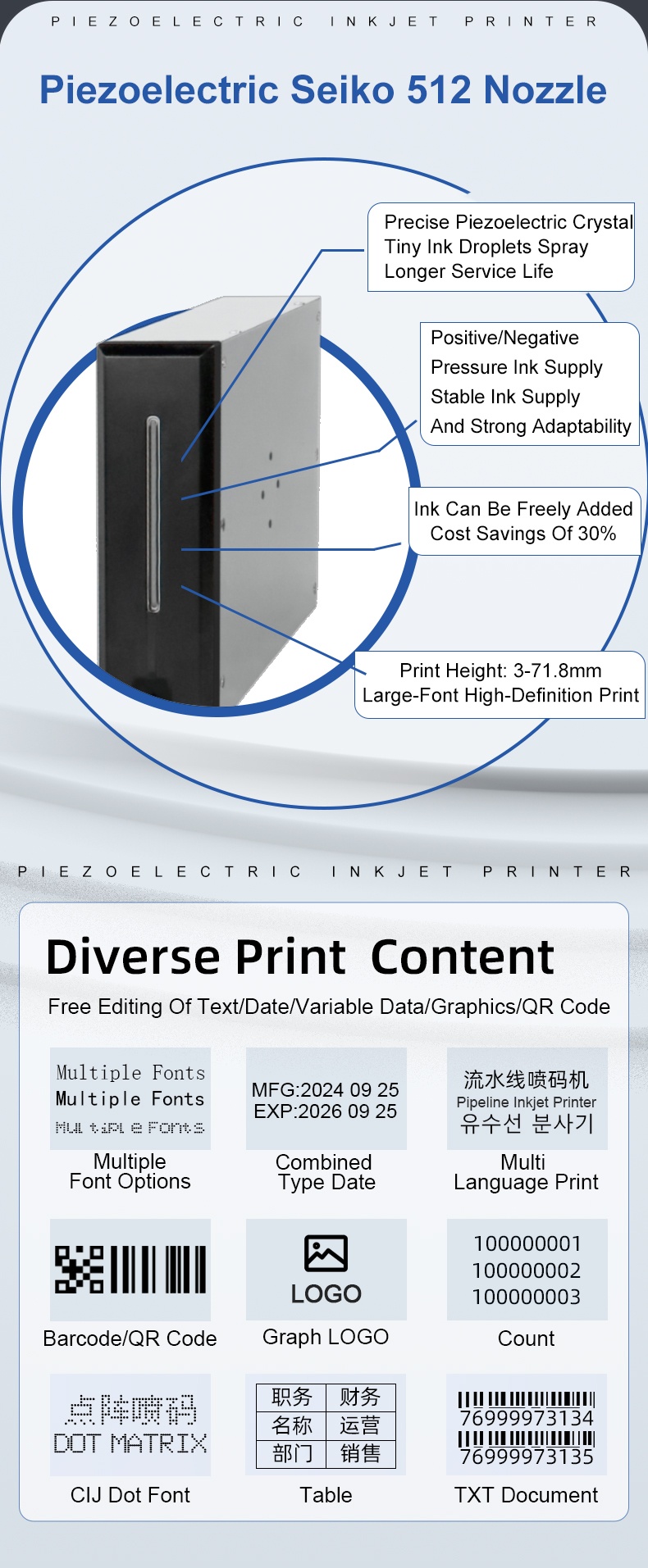

The core advantage of the P70 piezoelectric inkjet printer comes from the mature principle of piezoelectric technology: the nozzle integrates high-precision piezoelectric crystals, which control the crystal micro deformation to squeeze the ink chamber through electrical signals, forming uniform ink droplets for precise spraying. It can complete identification without heating, reducing energy consumption and extending the nozzle life. The mainstream models equipped with industrial grade precision 510 nozzles have a printing width coverage of 3-71.8mm and a resolution of 180-600DPI. Whether it is small product serial numbers, complex brand logos, or high fault tolerance QR codes and barcodes, they can achieve clear and delicate presentation, meeting the requirements of product compliance and traceability management.

Efficient adaptation and stable durability are the key to its establishment in industrial scenarios. The device supports high-speed printing at a speed of 100 meters per minute and can seamlessly connect with various production lines. It is also compatible with various environmentally friendly inks such as water-based, solvent based, UV curing, etc., with no VOC emissions, which is in line with the trend of green production. Its modular design can flexibly adapt to copperplate paper PET、 Multiple material surfaces such as cardboard boxes can be accurately coded, even for slightly curved or uneven workpieces. With intelligent tension control and electrical signal negative pressure adjustment, clogging and ink leakage problems are eliminated, ensuring 7x24 hour continuous operation stability.

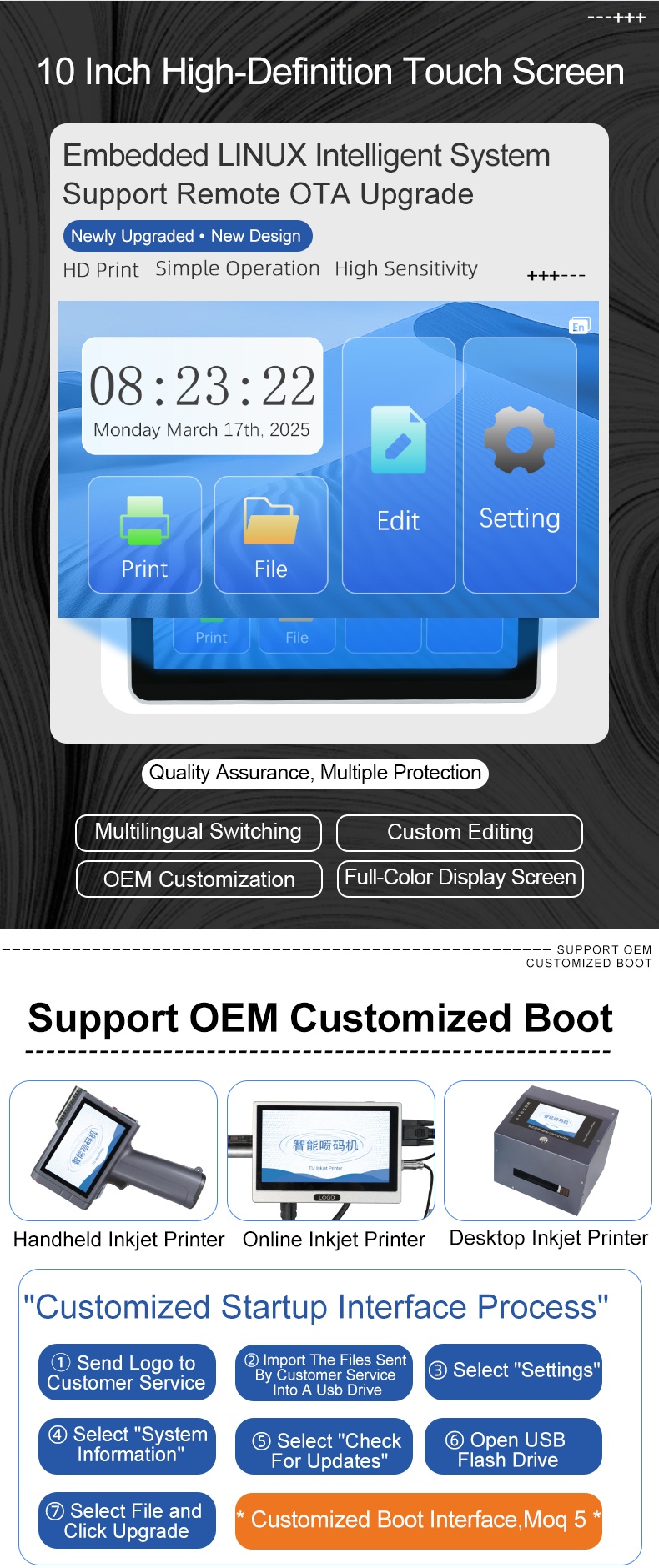

The convenience of operation and humanized design further reduce the threshold for use. Equipped with a 10.1-inch high-definition touch screen, it supports pinyin, handwriting, and multilingual input, with multiple built-in fonts and barcode templates. It can directly import text, images, and database files, making it easy for beginners to get started. The total weight of the machine is only 3.5kg, with a compact appearance (25516835mm), supporting both handheld and online operation modes, and meeting the needs of mobile coding and fixed printing on the assembly line. It is widely used in multiple industries such as food, chemical, hardware, and home textiles. In addition, the one-year warranty service and simple maintenance process significantly reduce the overall lifecycle cost of the equipment.

From printing the production date of food packaging, to batch tracing of electronic components, and to assigning large QR codes to logistics cartons, the P70 piezoelectric inkjet printer breaks the performance limitations of traditional labeling equipment with its core characteristics of "high definition, high efficiency, environmental protection, and flexibility", becoming a powerful assistant for enterprises to reduce costs, increase efficiency, and comply with production regulations, and promoting the upgrading of the labeling industry towards intelligence and green direction.