scpmkj@gmail.com

Get A Free Quote

Label rewinder: a powerful tool for ensuring identification in automated production

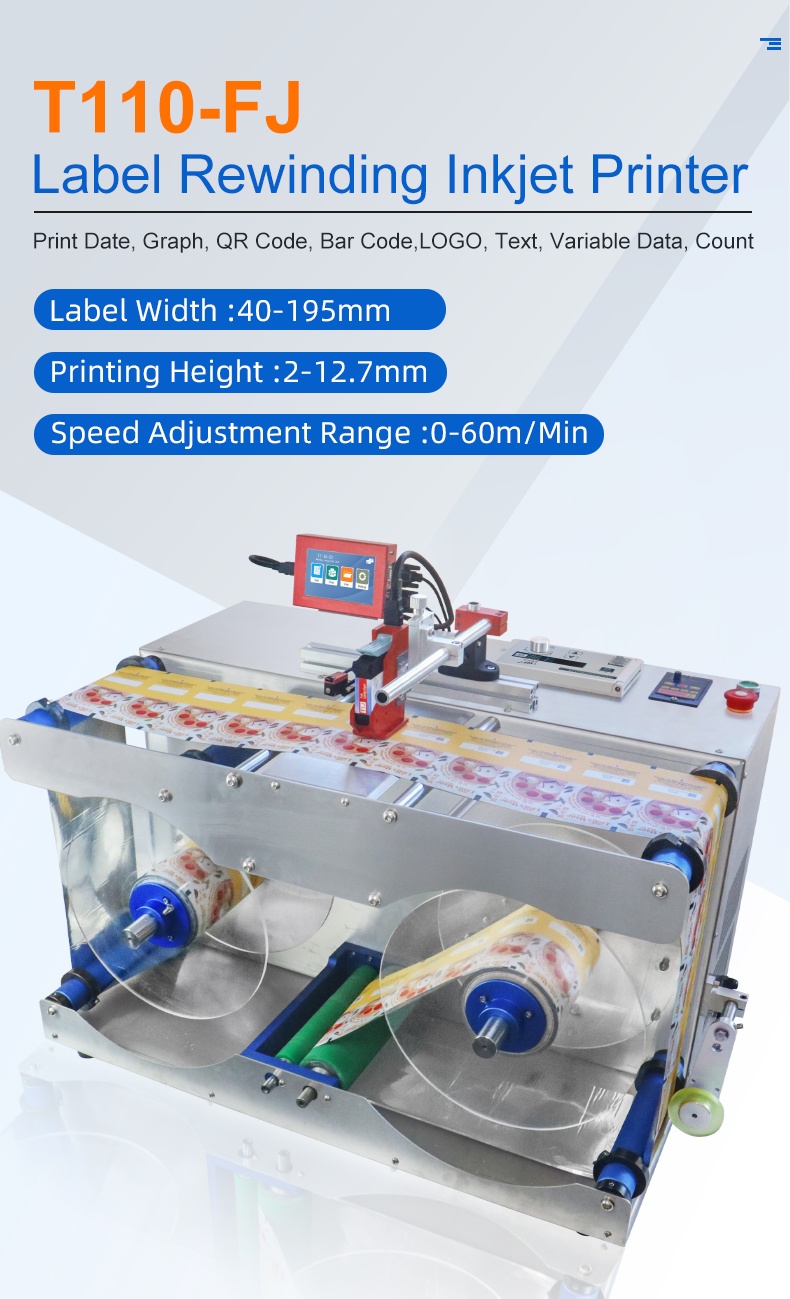

In modern production scenarios such as logistics sorting, food packaging, and electronic manufacturing, standardized label winding is a key link to ensure efficient operation of subsequent labeling. As an automated equipment that replaces manual winding, label rewinding machines have become the core equipment for enterprises to reduce costs and increase efficiency, thanks to their precise control and efficient adaptation capabilities.

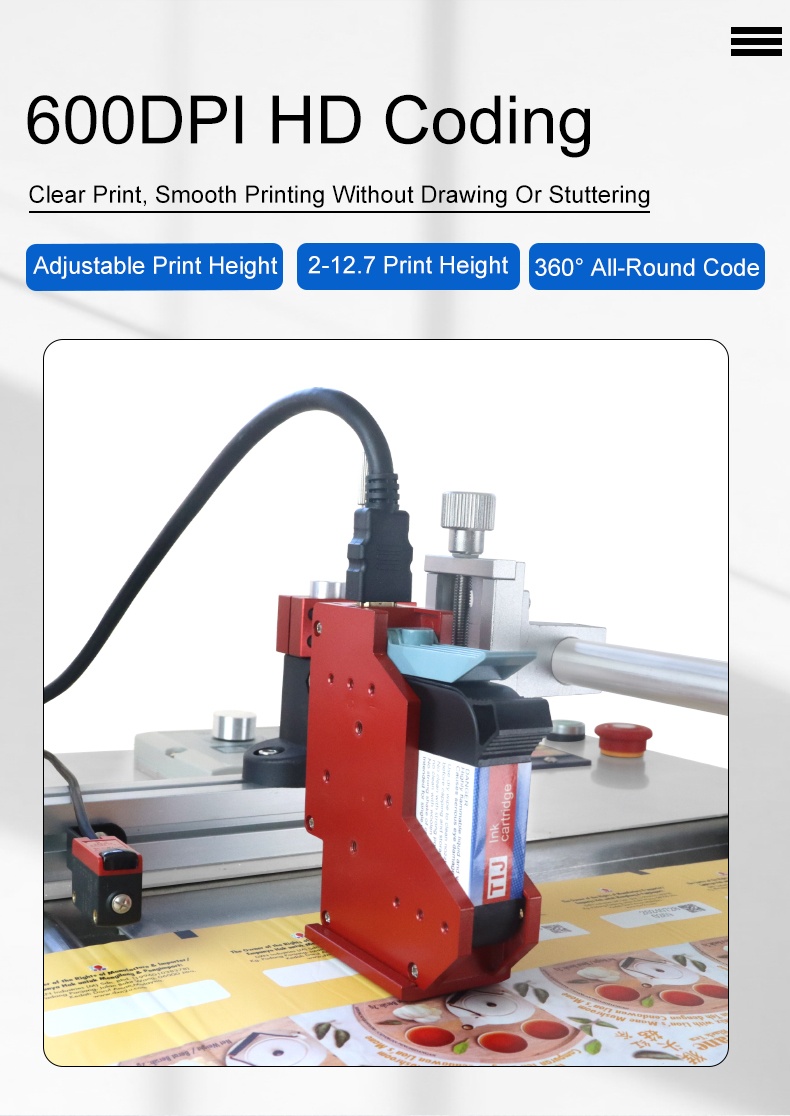

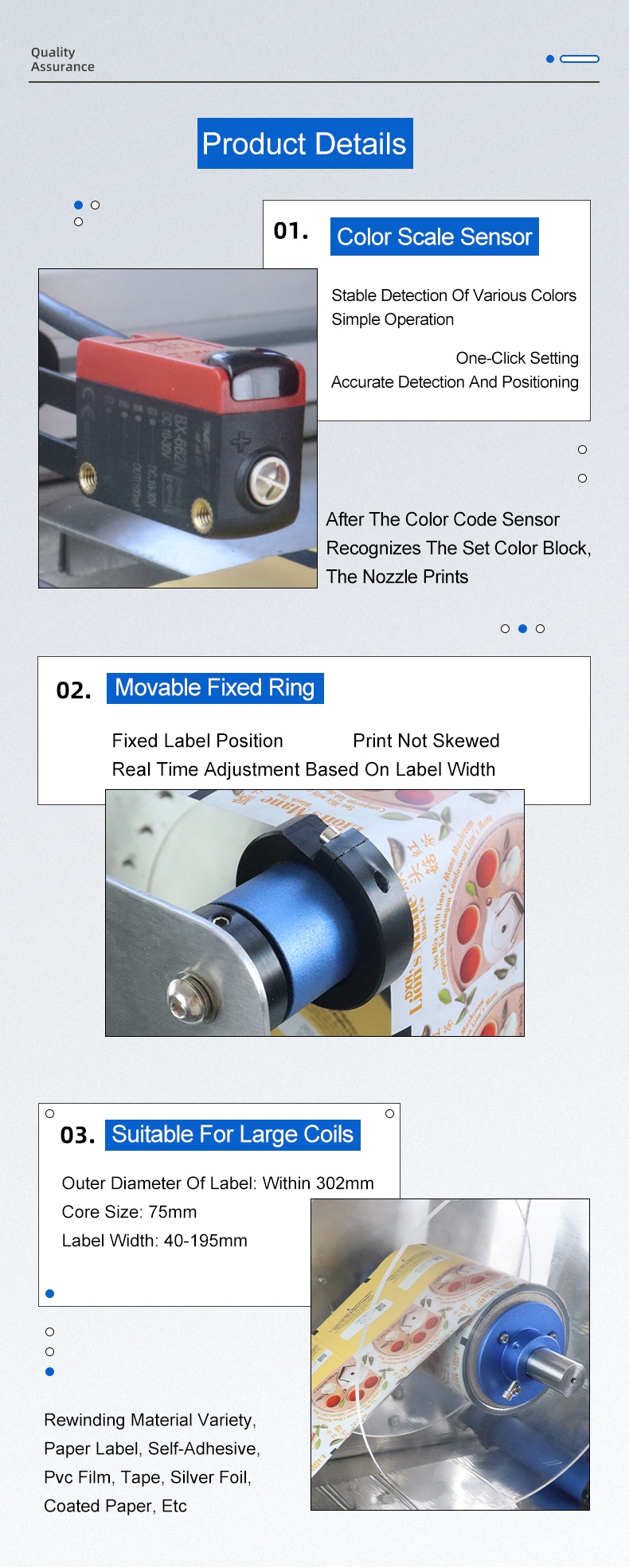

Its core advantages are concentrated in three dimensions: first, precision tension control, which adapts to changes in roll diameter in real time through servo motors and closed-loop algorithms, ensuring that the labels are evenly stretched, wrinkled, or broken from empty roll to full roll, eliminating stretching, wrinkling, or breakage problems; Secondly, it has strong compatibility. The modular design can quickly adapt to labels with different widths ranging from 20mm to 300mm, and is compatible with copperplate paper PET、 Multiple materials such as washing labels, supporting various core specifications of 1-3 inches, can be easily accessed with just one click during production changes; Thirdly, it is stable and durable, using high-strength alloy frame and international first-line brand transmission components, which can meet the 7x24 hour continuous operation requirements, with an average time between failures far exceeding industry standards.

The operation level is more user-friendly, with an intuitive touch screen and automatic counting and fault self diagnosis functions, making it easy for beginners to get started quickly; The transparent protective cover and emergency stop button create multiple safety protections, and daily maintenance does not require special tools. From high-speed rewinding of logistics waybills, to compliance labeling and winding of food and drug products, to precision label processing of electronic components, label rewinding machines seamlessly connect with mainstream printers, increasing manual efficiency by more than three times and significantly reducing material loss. They have become a key link in connecting production processes and ensuring labeling quality, promoting automation upgrades in various industries.