scpmkj@gmail.com

Get A Free Quote

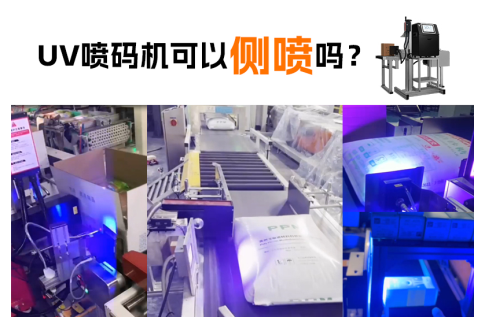

In the fast-paced field of printing technology, there is a constant need to innovate and improve printing methods. A breakthrough in recent years has been the emergence of UV inkjet printers. These cutting-edge devices have revolutionized the printing industry with their side-spraying capabilities, resulting in higher quality and more efficient print jobs.

UV inkjet printers use ultraviolet (UV) technology to cure ink almost immediately after contact with the medium. Compared to traditional printing methods, this technology has many advantages, such as faster drying times, higher durability and vivid color reproduction. However, what really sets the UV printer apart is its unique side spray function.

Side spraying is a technology used by UV printers that allows ink to be sprayed at an angle perpendicular to the surface rather than directly from above. This innovative method improves print quality by reducing dot gain and the appearance of unwanted artifacts. Side-jet printing allows UV inkjet printers to achieve higher resolution and clarity than traditional inkjet printers, which often rely on a single print, especially when printing small or complex designs.

Another significant advantage of side painting is its ability to retain finer detail and maintain consistent color reproduction throughout the print job. This is particularly important in industries such as packaging, product labeling and graphic design, where every small element is important. By accurately controlling ink deposition by side-jet printing, UV printers can accurately reproduce delicate designs, complex patterns and tiny text without sacrificing clarity or clarity.

In addition, side spraying greatly reduces ink waste because it minimizes overspray and ensures that ink is applied only where needed. This efficiency not only saves costs, but also benefits the environment by reducing overall ink consumption. In addition, the UV inkjet printer with side spray function can process a variety of substrates, from paper and cardboard to plastics and metals, making it ideal for a variety of printing applications.

Integrating side-spray technology into UV printers opens up new areas of possibilities for companies and creative professionals. With this advanced technology, they can now explore more complex designs, push the boundaries of printing capabilities, and provide superior print quality that transcends traditional methods.

However, it is worth noting that UV inkjet printers with side spraying function are generally more expensive than traditional printers. The cost of such printers can be prohibitive for small businesses or individuals. In addition, the initial setup and calibration process requires professional and technical knowledge, which can also pose challenges for some users.

To sum up, UV inkjet printers with side-spray function have completely changed the printing industry, providing unparalleled print quality, higher efficiency and versatility. This groundbreaking technology allows businesses and creative professionals to create high-resolution, complex designs with consistent color reproduction. While cost and technical requirements may be obstacles for some, the advantages of side-spray UV printers make them a valuable asset for those seeking best-in-class printing solutions. As technology continues to advance, it is exciting how UV printers will further develop and change the printing world.