scpmkj@gmail.com

Get A Free Quote

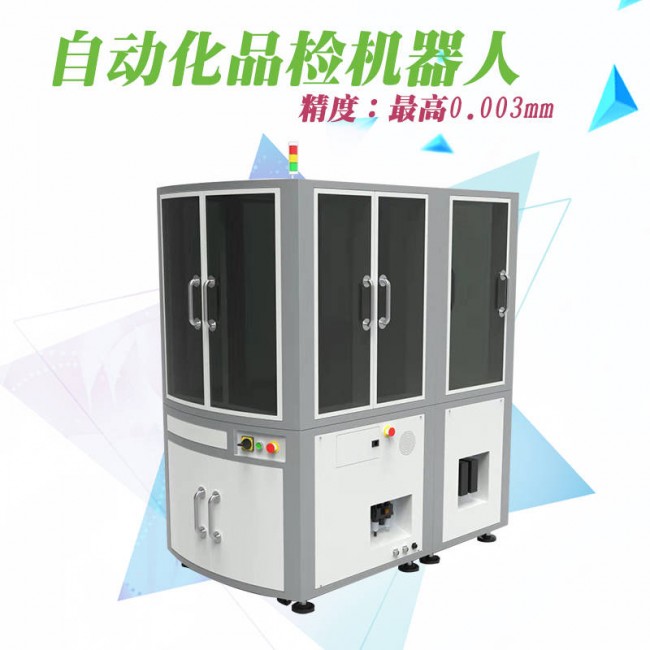

In today's highly automated industrial manufacturing field, product appearance defect size detection is a crucial task. Traditional manual detection methods often have many difficulties, such as low detection efficiency, poor accuracy, and strong subjectivity. The emergence of fully automatic visual online inspection equipment provides an effective way to solve this problem.

Machine vision technology has been widely used in many industrial manufacturing companies and is increasingly recognized and favored by users. Machine vision replaces the human eye in making judgments, using an industrial CCD camera to capture images of the target product and send them to a computer or a dedicated image processing module. Through digital processing, size, color and shape characteristics can be determined based on information such as pixel distribution, brightness and color. Then based on the judgment results, the next action of the on-site device is controlled to eliminate and classify defective products. Fully automatic visual online detection of size appearance defects contactless visual inspection effectively prevents defective products from being delivered to customers and causing adverse effects. Its detection functions have dozens of immeasurable value.

Fully automatic visual online inspection equipment is widely used in various industrial manufacturing fields, such as automobile manufacturing, electronics manufacturing, machinery manufacturing, etc. In these fields, product appearance defect size detection has always been a problem. For example, strict quality control of the body is required during the automobile manufacturing process to ensure the safety and stability of the vehicle. Electronic manufacturing and mechanical manufacturing also require fine appearance inspection of products to ensure product quality and accuracy. The application of fully automatic visual online inspection equipment makes appearance defect size detection in these fields more efficient and reliable.

1. The efficiency of automated visual inspection equipment

CCD vision inspection equipment arranges products in an orderly manner through a vibrating plate, assembly line or robot, and then transfers them to the front end of a straight track. The conveyor belt or vibrating plate operation drives the product under the industrial camera model for machine vision quality inspection and collects data images. This information is transferred to optical vision software by the collected images to calculate and analyze good and poor qualities. This automated testing process greatly improves production efficiency and reduces the cost of manual testing.

2. Advantages and characteristics of CCD vision inspection equipment

High efficiency: CCD vision inspection equipment can continuously and quickly detect products, and its detection speed is much higher than manual detection, thereby improving production efficiency.

Low cost: Compared with manual inspection, CCD vision inspection equipment has lower operating costs. They can be tested in real time during the production process without taking breaks, greatly reducing labor costs.

High precision: CCD vision inspection equipment uses advanced algorithms and image processing technology to accurately identify and measure various parameters and defects of the product, such as size, shape, surface quality, etc. This high-precision detection capability is difficult to achieve by manual testing.

Objectivity: Different from human subjective thinking, the judgment of CCD visual inspection equipment is objective. They are not affected by factors such as human fatigue, mood, and senses, so they can provide more stable and reliable test results.

CCD vision inspection equipment has a wide range of application fields, including high-precision and efficient manufacturing industries such as hardware, plastics, and electronic parts. In these fields, CCD vision inspection equipment can replace artifact inspection, improve production efficiency, and bring new opportunities and development to the development of the manufacturing industry.

CCD vision inspection equipment has significant advantages in product appearance defect size detection and defective product sorting. They can improve production efficiency, reduce costs, provide high-precision test results, and are objective. These characteristics make CCD vision inspection equipment have broad application prospects in the manufacturing industries of hardware, plastics, electronic parts, etc. With the continuous advancement and innovation of technology, we have reason to believe that CCD vision inspection equipment will play an increasingly important role in the future manufacturing industry, bringing more opportunities and development to the development of the manufacturing industry.