scpmkj@gmail.com

Get A Free Quote

Paper product packaging is a large-scale type in packaging industrial products. The carton is a three-dimensional shape, which is composed of a multi-faceted body formed by moving, stacking, folding and enclosing several composed surfaces. Cartons must be included in the packaging of goods, and the content introduction of the goods on the surface of the carton. Most packaging companies prefer a single carton inkjet printer as a content identification device, such as variable QR codes, barcodes, electronic supervision codes, quantum cloud codes, patterns, texts, etc., installing production lines works quickly and improves work efficiency. The key is that its own performance advantages are obvious and have very large market potential. It continuously accelerates the production process of the company and protects people's health and safety.

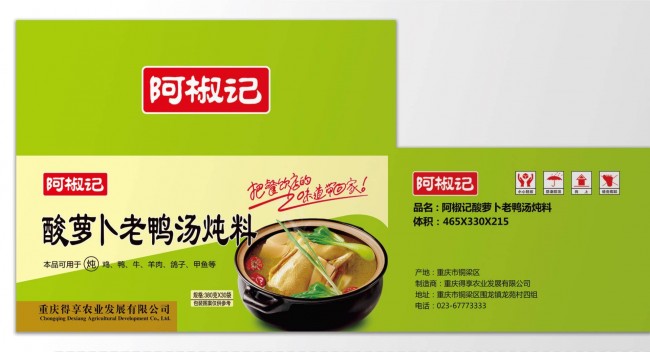

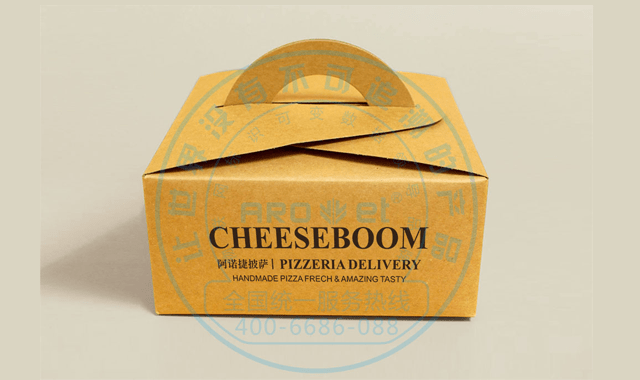

Carton spray printed sample map

Single-carton inkjet printers continue to enter the production auxiliary equipment of the packaging industry with their flexibility, and use their own skills to continuously create more advantages, and bring more reliable products to users with high-efficiency production methods. As industrial marking equipment, UV inkjet printers are well used in product marking in various industries, especially in the field of product packaging. They are installed on the production line, and the speed can be adjusted according to customer needs. Platform control. When the cartons are transported from the assembly line, after the photoelectric sensor of the inkjet printer sends a signal, the system will code the code according to the set time to achieve automated work and create a more flexible and reliable digital coding system.

Carton spray printed sample map

The single-carton inkjet printer adopts industrial piezoelectric nozzles and has a powerful variable data editing and intelligent control printing system to meet the printing needs of different user data. The open third-party interface can cooperate with ERP, anti-counterfeiting systems, PLC and other customer systems to perform timely data and information printing. The inkjet printer can be installed on the customer's existing various rotary printing equipment, flexo presses, gravure presses and other equipment, pre-press and post-press processing equipment, packaging equipment and other online assembly line equipment.